Dongguan sidi ke anti - static technology co. LTD 粤ICP备15079615号

Dongguan sidi ke anti - static technology co. LTD 粤ICP备15079615号

High-frequency DC ion nozzle with built-in subminiature piezoelectric transformer.

This product is designed by professionals, with less brackets, convenient installation and direction adjustment.

Mainly used in electronic assembly line, painting industry, medical machinery manufacturing and packaging, semiconductor production and flat panel display manufacturing, packaging, injection molding production, photoelectric and other industries.

Product Features:

High reliability: Adopt air connector to improve ozone resistance.

Ensure safety: Adopt transformer box with new structure, and stop high voltage output when cleaning and replacing discharge needle

Nozzles with improved ozone resistance: All kinds of nozzles with high ozone resistance

Easy to maintain: The discharge needle is detachable and easy to maintain, and can be pulled out together with the transformer from the rear to clean and replace the discharge needle conveniently.

High-voltage stop alarm: It has alarm display function during high-voltage stop and is equipped with normally open and normally closed double contacts without signal contact.

Clean check "C.C": It is also equipped with normally open non-signal contact

Technical Parameter

| Input power supply: | DC+24V±10% |

| Capacity: | 2.4VA |

| Output voltage: | High frequency 3000V |

| Ion balance: | Under ±10V |

| Use air pressure: | 0.05Mpa~0.6Mpa |

| Air flow: | 30L/min~160L/min |

| Ozone generation: | Under 0.05ppm (input air pressure: 0.02Mpa, measuring distance: 300mm) |

| Working guarantee temperature: | 10~40℃ (Save at -10℃~60℃) |

| Work guarantee humidity: | ~75% or less, but no condensation (keep it below -90%, no condensation) |

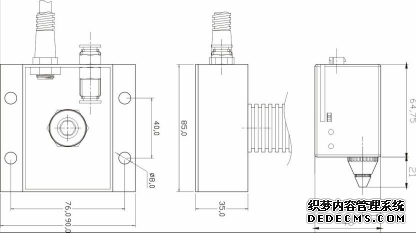

| Main body size: | 87×23×41mm(L×W×H) (including protrusion, size of individual nozzle head) with a total length of 650mm including base |

| Main body weight: | 1.35kg |

| Attachments: | Enter power cable + Nozzle + Instruction manual |